Tietosuojalausunto: Yksityisyytesi on meille erittäin tärkeä. Yrityksemme lupaa olla paljastamatta henkilökohtaisia tietojasi mille tahansa laajentumiselle ilman nimenomaista käyttöoikeustasi.

Ms. Shelby Luo

Mitä voin tehdä puolestasi?

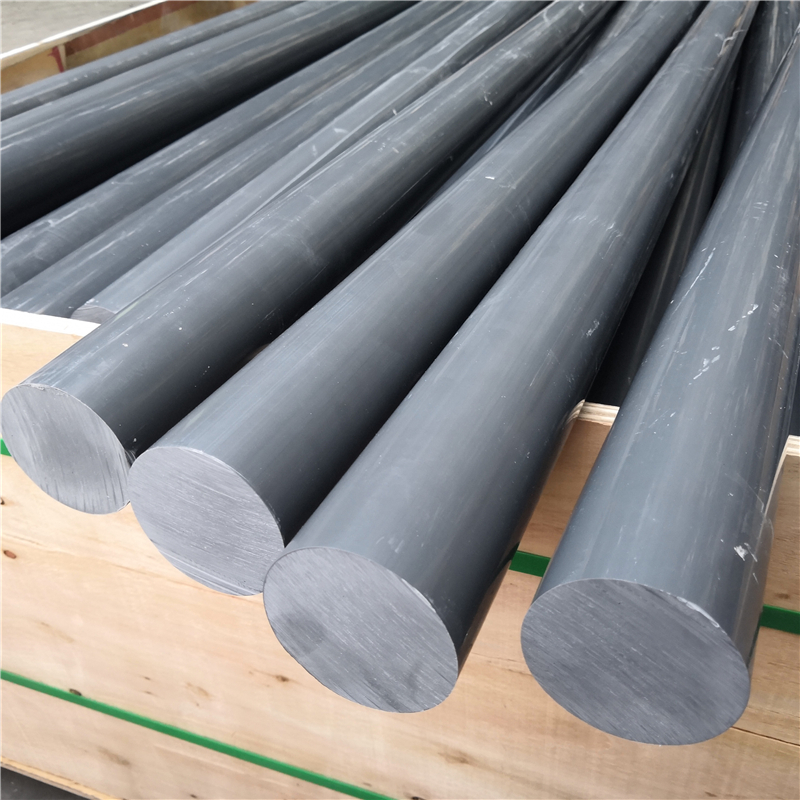

Product name PVC rod: English name Polyvinyl Chloride, Chinese polyvinyl chloride rod, is a flame-retardant, chemically stable, non-crystalline material that only produces low tensile cracking internal force. It is the first in China and the second largest in the world. Synthetic resin materials, due to their excellent flame retardancy, abrasion resistance, chemical resistance, comprehensive mechanical properties, product transparency, electrical insulation and relatively easy processing characteristics, currently, PVC has become the most widely used plastic One of the varieties, widely used in industry, construction, agriculture, daily life, packaging, electricity, public utilities and other fields, collectively referred to as polyethylene (PE), polypropylene (PP), polystyrene (PS) and ABS Five general-purpose resins.

Main features

PVC has excellent electrical insulation and generally does not burn. It can burn on the flame and release HCl, but it will self-extinguish when it leaves the flame. It is a "self-extinguishing" and "flammable" substance. Based on the above characteristics, PVC is mainly used in the production of profiles, profiles, pipes, rods, plates, sheets, cable sheaths, hard or soft tubes, blood transfusion equipment and films.

Molding characteristics

1. Amorphous material, low moisture absorption, poor fluidity. In order to improve fluidity and prevent bubbles, the plastic can be dried in advance. The mold casting system should be thick and short, the gate section should be large, and there should be no dead corners. The mold must be cooled and the surface is chrome-plated.

2. Due to its corrosive and fluid characteristics, it is best to use special equipment and molds. All products must be added with different types and quantities of additives according to needs.

3. It is easy to decompose, and it is easier to decompose in contact with steel at a temperature of 200 degrees. Copper will be more easily decomposed when it is decomposed, and it will escape corrosive gas. The molding temperature range is small.

4. When the screw injection machine nozzle is used, the aperture should be large to prevent dead ends from stagnating. It is better to have no inserts, and if there are inserts, they should be preheated.

The melting temperature of PVC during processing is a very important process parameter. If this parameter is not appropriate, it will cause material decomposition. The flow characteristics of PVC are quite poor, and its process range is very narrow. In particular, PVC materials with large molecular weights are more difficult to process (such materials usually need to be added with lubricants to improve flow characteristics), so PVC materials with small molecular weights are usually used. The shrinkage rate of PVC is quite low, generally 0.2~0.6%.

Scope of application

PVC rod

Strong corrosion resistance: most suitable for anti-corrosion equipment. It is easy to process, cutting, welding and bending. High strength, high stiffness and high hardness; good electrical insulation; good chemical stability; self-extinguishing; low water absorption; easy to bond, easy to paint, low price.

July 03, 2023

July 03, 2023

January 27, 2021

Lähetä tämä toimittaja

July 03, 2023

July 03, 2023

January 27, 2021

Tietosuojalausunto: Yksityisyytesi on meille erittäin tärkeä. Yrityksemme lupaa olla paljastamatta henkilökohtaisia tietojasi mille tahansa laajentumiselle ilman nimenomaista käyttöoikeustasi.

Täytä lisätietoja, jotta voit ottaa sinuun yhteyttä nopeammin

Tietosuojalausunto: Yksityisyytesi on meille erittäin tärkeä. Yrityksemme lupaa olla paljastamatta henkilökohtaisia tietojasi mille tahansa laajentumiselle ilman nimenomaista käyttöoikeustasi.